UV Curing and Printing

Tailored UV LED solutions for diverse printing and curing applications

In the realm of printing and curing, bespoke solutions are paramount for achieving optimal results. PRP specialises in tailoring UV LED solutions for diverse printing and curing applications. We work closely with our clients to deliver customised UV LED solutions, ensuring precision and efficiency in every bespoke application.

PRP’s legacy in innovation positions it as a trusted leader in the optoelectronics industry with over 35 years’ experience. Having a keen focus on research and development, PRP has consistently been at the forefront, earning a reputation for delivering unique high quality engineered solutions.

Understanding Your Needs

Our approach begins with a friendly flexible approach to thoroughly understand what our clients’ specific needs are for printing and curing applications. Throughout this journey of development, we aim to meet the unique requirements of the application needed.

- Client Collaboration: PRP initiates a comprehensive consultation to understand the intricacies of the client’s printing and curing requirements. This includes the materials involved, desired curing or printing speed, and specific parameters crucial for success.

- Application-Centric Design: Leveraging advanced optical modelling tools, PRP designs UV LED configurations that are optimised for the unique demands of each application. The focus is on achieving maximum efficiency, precision, and coverage while minimising energy consumption.

- Flexible Customisation: PRP offers a spectrum of customisation options, encompassing various wavelengths, power levels, and beam geometries. This flexibility ensures that the final UV LED solution is precisely tailored to the bespoke requirements of the application.

Bringing Concepts to Reality

PRP’s commitment to excellence extends into the development phase, ensuring that bespoke UV LED solutions not only meet but exceed stringent quality standards.

- Material Selection for Durability: PRP uses high-quality semiconductor materials to enhance the durability, reliability, and efficiency of the UV LED solutions.

- Prototyping and Testing: Prototypes undergo rigorous real-world testing, allowing for iterative adjustments and optimisations before production. This meticulous process ensures the final solution aligns seamlessly with the bespoke application.

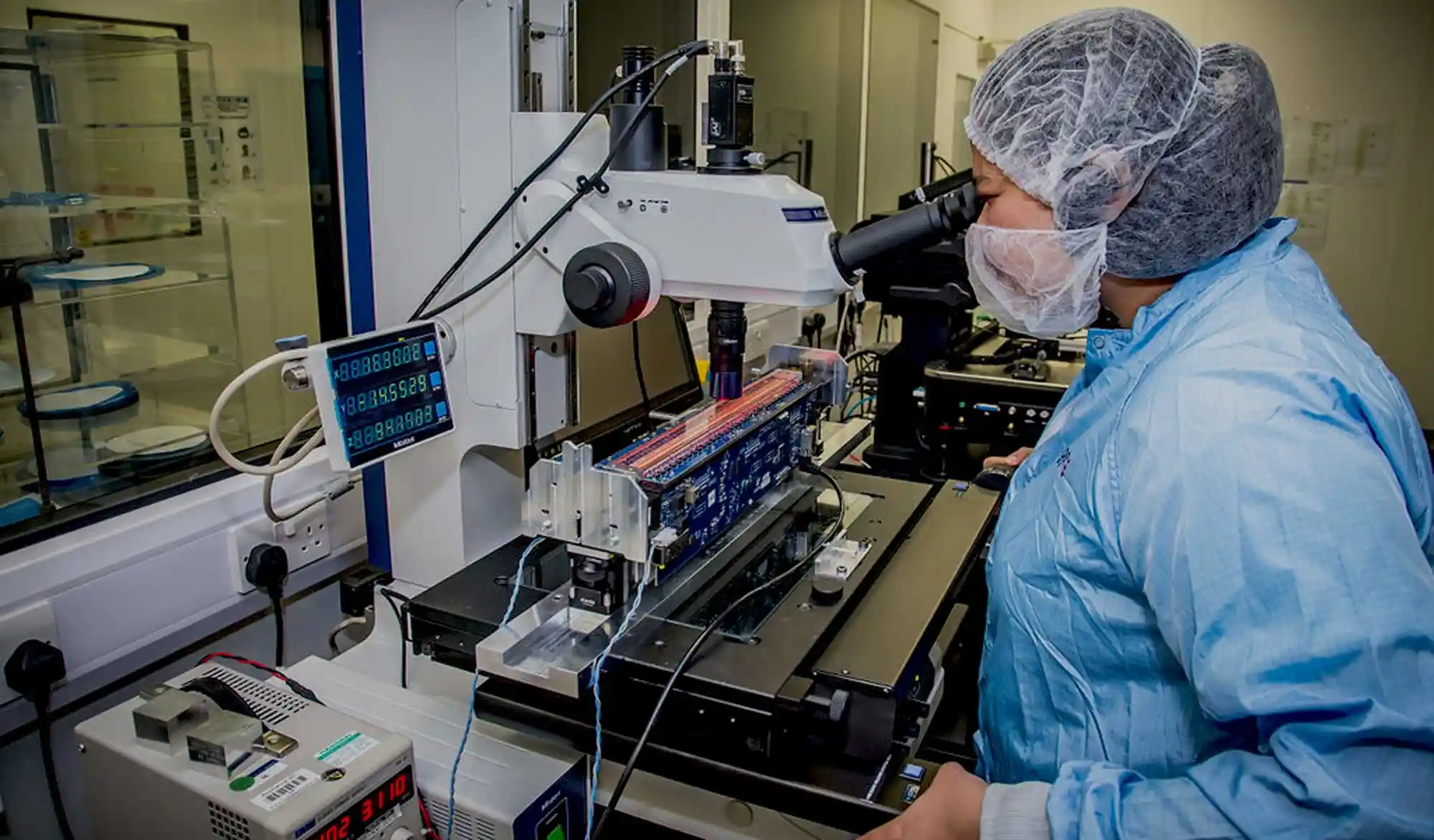

- Stringent Quality Assurance: Every UV LED unit undergoes stringent quality control measures, covering thermal stability, optical performance, and overall durability. This ensures the consistency and reliability of bespoke solutions.

Manufacturing Expertise – Precision at Scale

PRP’s manufacturing capabilities are designed to deliver precision no matter the scale, ensuring that each UV LED unit maintains the highest standards.

Automated & Scalable

Automated Precision Assembly: Cutting-edge automated assembly lines streamline the manufacturing process, minimising errors, and ensuring precision in every unit.

Scalable Production: PRP possesses the capacity to scale production according to the volume requirements of clients, ensuring timely delivery of customized UV LED solutions for printing and curing applications.

Energy-Efficient Solutions

As an industry leader, PRP prioritises sustainability and environmental consciousness in its operations.

PRP’s design and manufacturing processes prioritize energy efficiency, contributing to reduced power consumption during the operational life of bespoke UV LED solutions.

Future-Ready Innovation

In a rapidly evolving technological landscape, PRP remains dedicated to future-ready innovation, continually investing in research and development to anticipate emerging trends and ensure bespoke UV LED solutions are cutting-edge and adaptable.